Top 5 Factors to Consider When Buying Ramming Mass

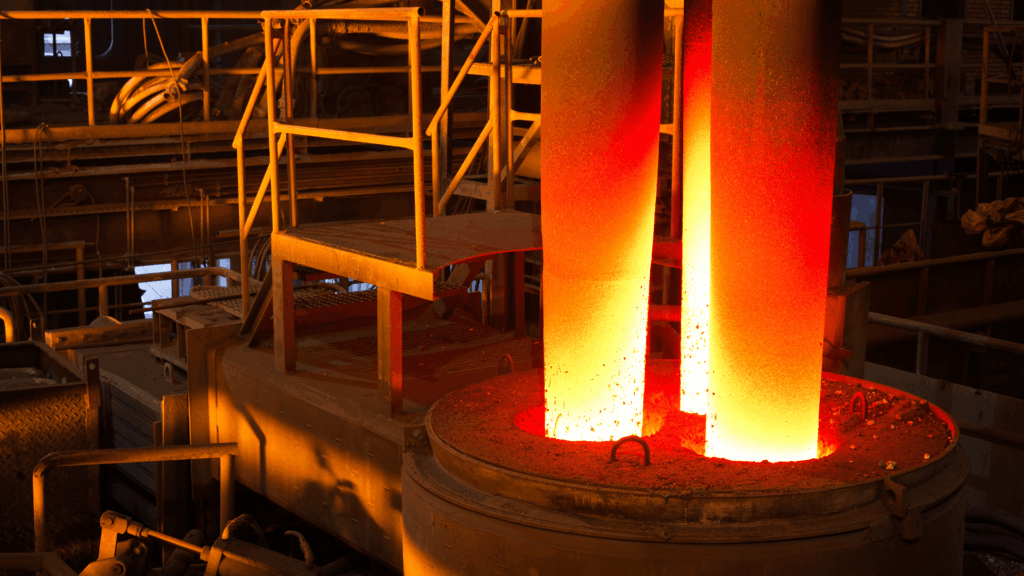

Top 5 Factors to Consider When Buying Ramming Mass Ramming mass is a vital component in the performance and lifespan of induction furnaces, so selecting it is an important decision for steel producers. Whether you require maximum thermal stability, higher furnace efficiency, or minimum downtime, optimal ramming mass selection can be the difference-maker. The following […]

Understanding Acidic Silica-Based Ramming Mass: Composition & Benefits

Understanding Acidic Silica-Based Ramming Mass: Composition & Benefits In the foundry and steel industries, refractory materials are important for the efficient operation of furnaces. Acidic silica ramming mass is one such vital refractory material used extensively for lining induction furnaces. This blog will give a clear idea about acidic silica ramming mass, its composition, and […]

Optimizing Induction Furnace Performance: A Professional Guide to Applying and Maintaining Ramming Mass

Optimizing Induction Furnace Performance: A Professional Guide to Applying and Maintaining Ramming Mass In the competitive secondary steel production sector, ensuring the efficiency and longevity of induction furnaces is paramount. A properly installed refractory lining, featuring high-quality ramming mass, not only minimizes downtime but also enhances energy efficiency and improves steel quality. At Monolithisch, we […]

The Role of Ramming Mass in Secondary Steel Production

The Role of Ramming Mass in Secondary Steel Production In the steel industry today, secondary steel production is vital for ensuring global need is met in high-quality steel. Ramming mass is one major ingredient that forms part of the process to be used with induction furnace lining. The performance, longevity, and cost-savviness of steel making […]